Related Queries

ToggleIf you’ve found signs of rats in your factory, you’ll want to deal with it quickly. You might have noticed droppings, chewed wires, damaged packaging, or even the odd scratching sound late at night. Whether you’ve seen one rat or many, it doesn’t take long for a small problem to turn into something bigger. In a space like a factory — with food, warmth, hiding spots, and less human activity overnight — rats have everything they need to settle in.

Getting rid of them isn’t just about putting traps down and hoping for the best. You need a proper plan. One that doesn’t just move the rats around but gets them out for good — and stops them coming back.

Let’s walk through what you can do.

Start With a Proper Inspection

You can’t fix what you haven’t seen. That’s why the first thing you need to do is walk through the space.

Go room by room, if possible. Start at the edges — look behind machinery, under shelving, in corners and along skirting boards. Rats tend to stick to the sides of a room, so focus there.

What you’re looking for:

- Droppings (dark, pellet-like)

- Chewed materials (wood, plastic, wires)

- Greasy smears along walls or entry points

- Nesting materials like shredded cardboard or fabric

- Gnaw marks around skirting boards or pipes

If you’re walking through a quiet part of the factory, especially early in the morning or after a weekend, stay still for a moment. You might hear movement. Sometimes, rats will scurry as soon as they sense you.

Mark down where you find signs. These areas are your hot spots. That’s where you’ll need to focus your action.

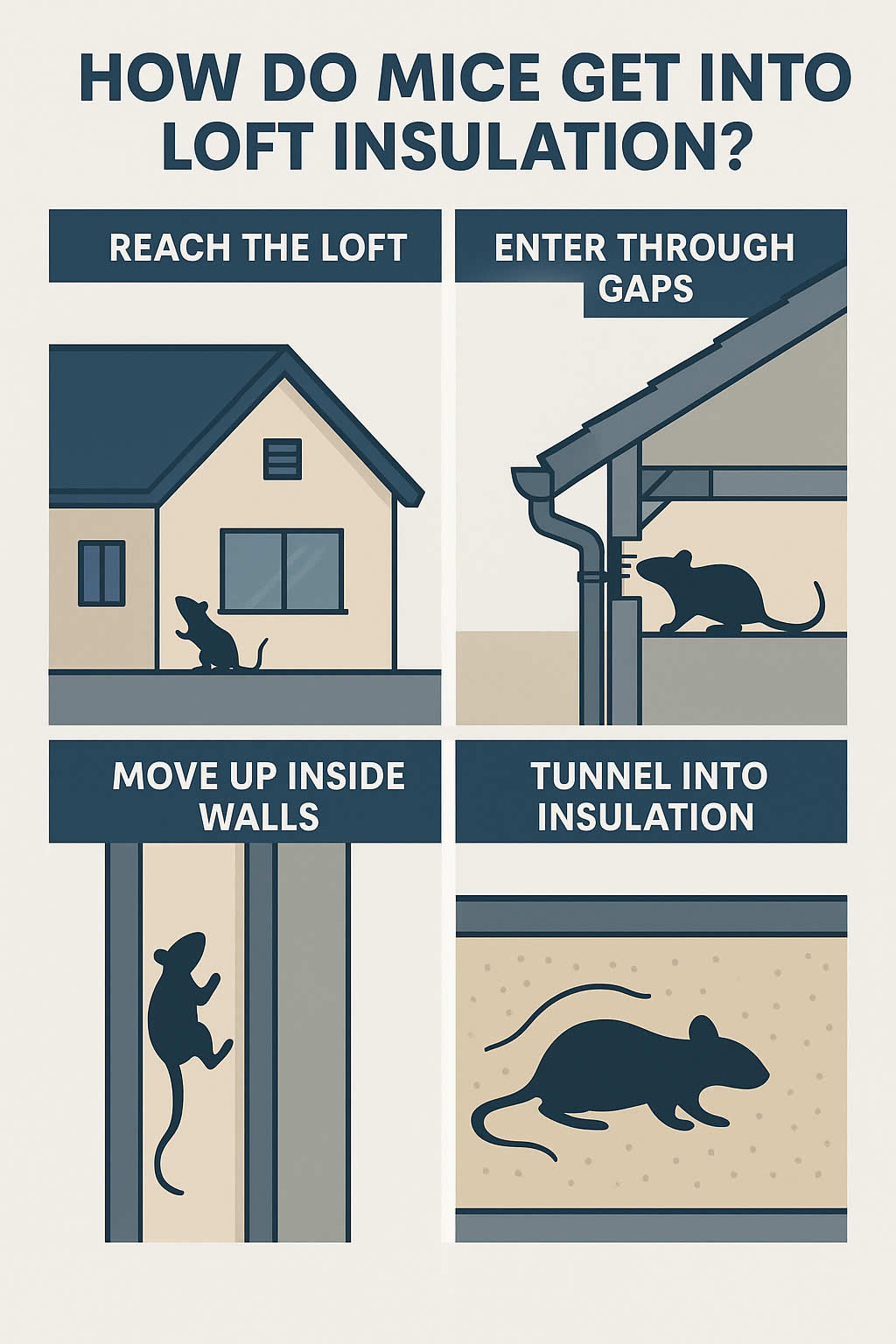

Find Out How They’re Getting In

This part’s just as important as getting them out. You need to know how they’re getting in — or you’ll be dealing with the same thing again next week.

Look around doors, vents, windows, pipe openings, loading bays, and roof lines. Rats only need a gap about the width of a thumb to get in. If they find a small crack, they can gnaw at it until it’s big enough.

Places you should check closely:

- Gaps around cables or pipework

- Broken brickwork or crumbling mortar

- Cracks in concrete or floors

- Doors that don’t close tight to the ground

- Openings around roller shutters

If you find one entry point, keep going. There’s often more than one.

Tidy Up the Environment

Rats come in because they’ve found food, warmth, and shelter. If you take away what they’re using, you make it harder for them to survive — and easier to get rid of them.

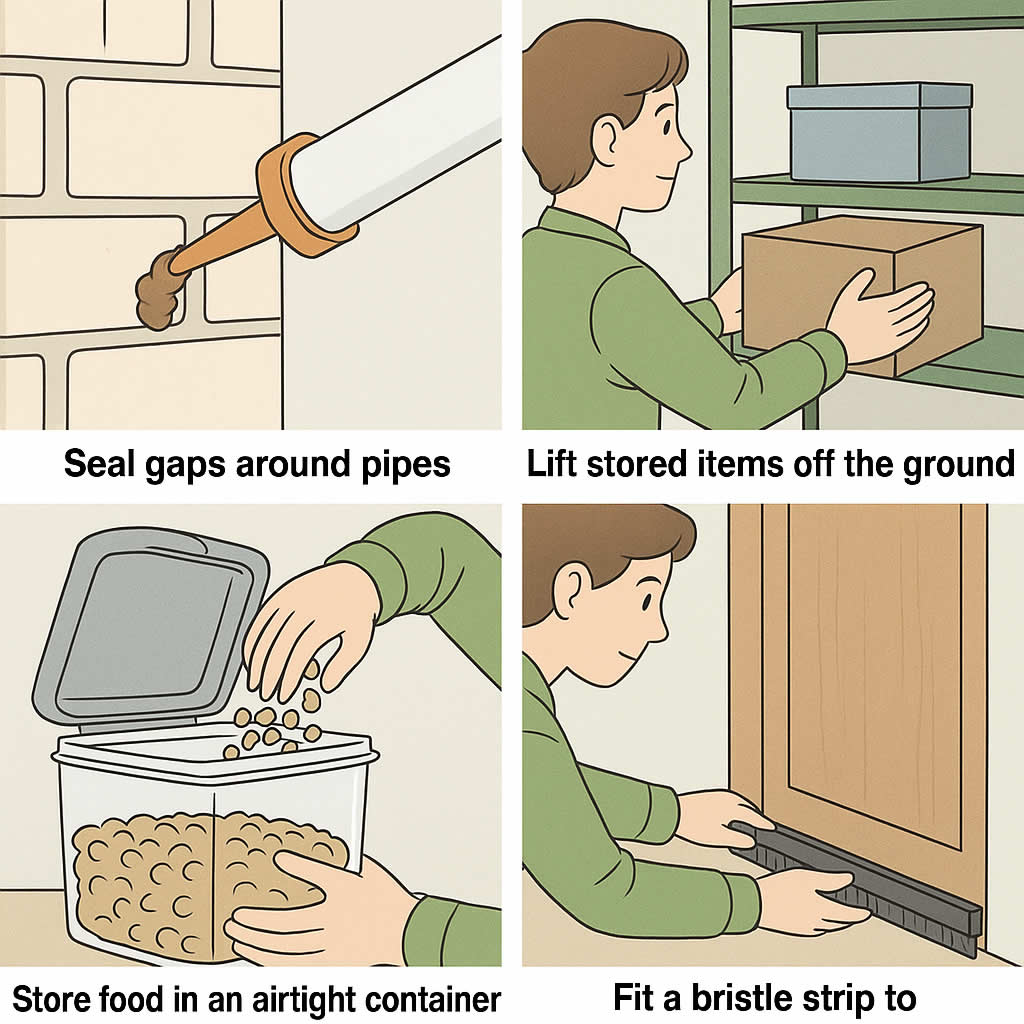

Start with food. Even if your factory doesn’t handle food products, there could still be things they eat. Crumbs from staff areas, waste in bins, or raw ingredients stored poorly.

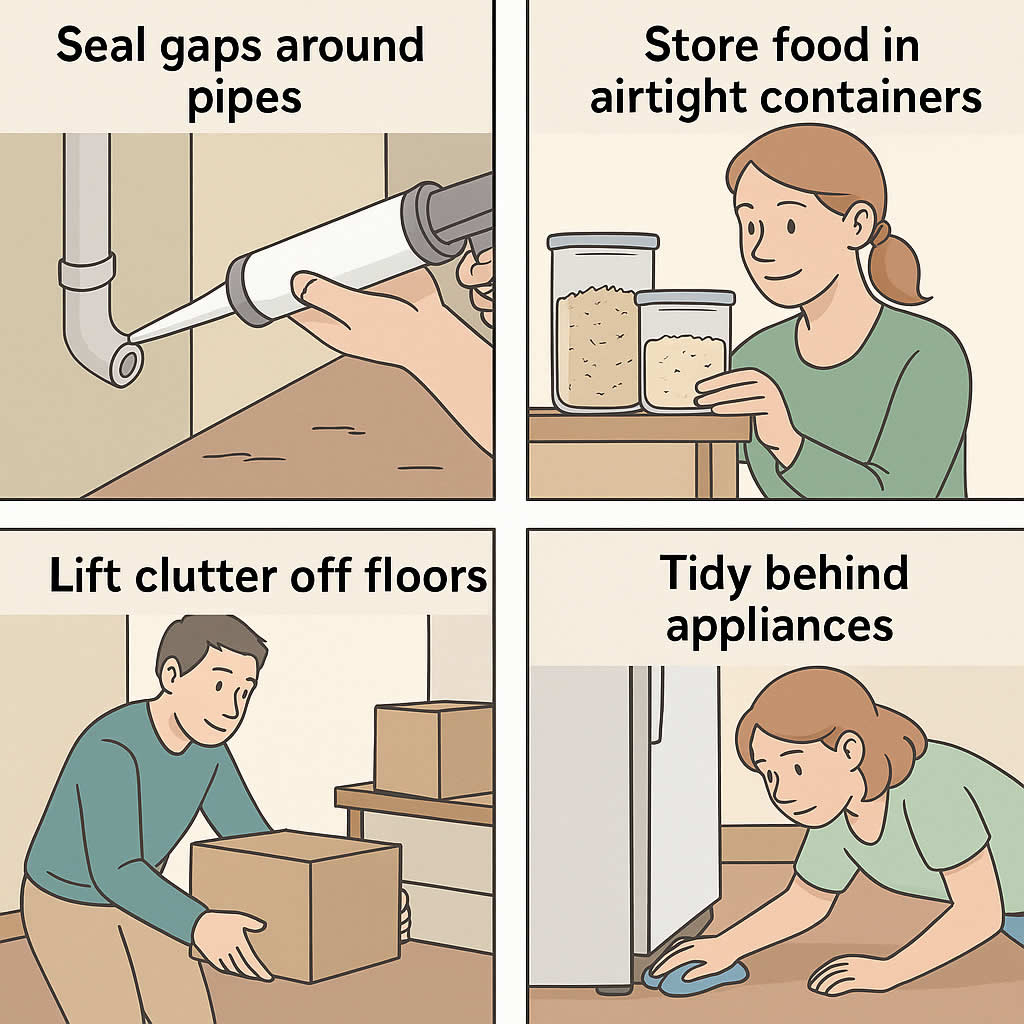

Then think about clutter. Piles of cardboard, unused pallets, bags of insulation, or messy corners all make perfect nesting spots. If a rat can hide undisturbed, it’ll stay.

What you can do:

- Keep bins sealed and empty them often

- Store materials off the ground and away from walls

- Clear out unused or broken equipment

- Sweep regularly, especially around machinery and staff rooms

- Make sure food is sealed in proper containers (if applicable)

The cleaner and more open the space is, the fewer hiding places they have.

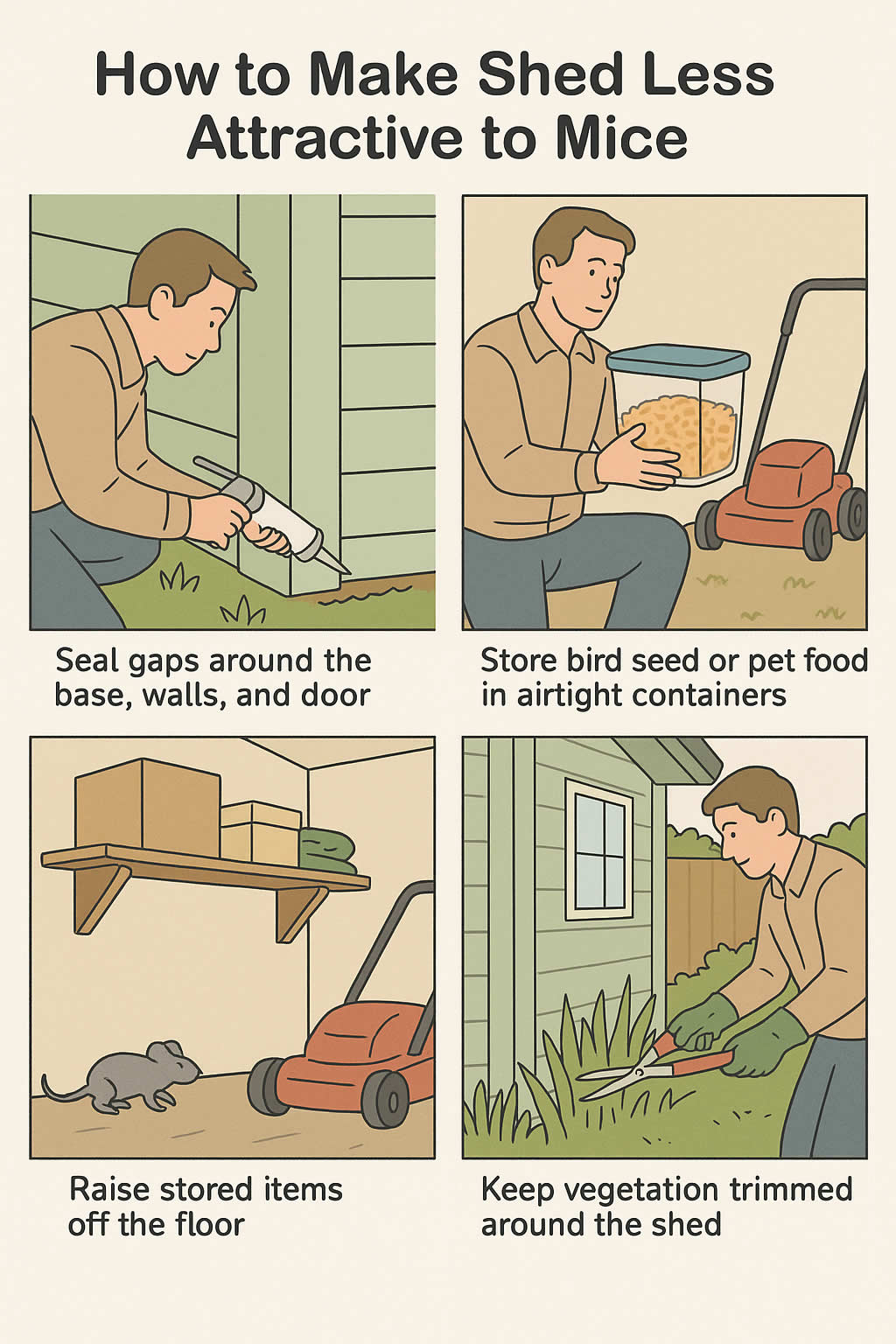

Block the Entry Points

Once you’ve found out how they’re getting in, you need to seal the gaps.

You can’t just patch it up with any material. Rats will chew through foam, wood, and even soft metal if they need to. So you want to use strong stuff — steel mesh, concrete, or metal plating.

Seal around:

- Door frames and loading bays

- Gaps around pipes and vents

- Broken brick or mortar joints

- Cracks along the floor or wall junctions

Don’t forget the roof space if you’ve got one. Rats can climb surprisingly well and might be using high points to get in. If you’ve got any open vents or gaps under eaves, cover them with wire mesh.

The more airtight your building is, the harder it’ll be for rats to get back in.

Choose the Right Removal Method

Now that you’ve inspected, cleaned, and sealed — it’s time to deal with the ones already inside.

There are a few options, and which one you choose depends on how bad the problem is and what your factory’s setup is like.

Traps

Snap traps are still one of the most reliable options. They kill instantly, so there’s no suffering, and you can check the numbers daily.

You should place them:

- Along walls and behind objects

- Near droppings or gnaw marks

- Close to suspected nest sites

Use bait like peanut butter, oats, or meat-based products. Rats are wary, so place rat traps without setting them for the first day or two — let them get used to the smell. Then, once they’ve started to show interest, you can set them.

Live traps are another option, but they need checking regularly. And you’ll need a plan for what to do with the rats once you’ve caught them.

Poison (Rodenticides)

Rodenticides can be effective, but they come with serious risks. You need to use the right product, in the right way, and with all safety precautions in place. That means using bait stations, keeping the bait locked up, and making sure staff and other animals can’t access it.

Also, poisoned rats might die in hard-to-reach places — behind machines, in wall cavities, or under the floor. That leads to odours and hygiene issues.

If you go this route, it’s best to do it under the guidance of a professional pest controller.

Bring in a Professional (If You Need To)

If it’s a large rat infestation or if you’ve tried to get rid of them before but they keep coming back, it might be time to call someone in.

A professional can:

- Work out how serious the problem is

- Set up a proper control programme

- Use commercial-grade traps and bait safely

- Give advice tailored to your factory’s layout

They’ll also give you a plan for long-term prevention, which can save you time and money in the long run.

Keep Checking After They’re Gone

You might think the job’s done once you’ve stopped seeing signs. But you still need to check regularly — especially in the first few months.

Walk through your factory every week. Look in the same places you checked before. Keep an eye on traps, even if you think they’re no longer needed. Watch out for signs like:

- New droppings

- Chewed materials

- Fresh smears on the walls

If something crops up again, you’ll spot it early — before it turns into a problem.

Set Up Ongoing Prevention

Now that you’ve cleared the rats out, your focus should shift to keeping them away. Prevention works best when it becomes part of your routine.

Here’s what you can build into your schedule:

- Weekly checks of problem areas

- Regular cleaning, including behind and under equipment

- Keeping bins sealed and emptied often

- Reporting gaps, cracks, or leaks as soon as they appear

- Storing goods off the floor and away from walls

Staff training can help too. If everyone knows the signs to watch for and understands the steps to take, you’ll catch problems faster.

If Your Factory Handles Food or Packaging

The pressure is even higher if your factory deals with anything that’s going near food, packaging, or pharmaceuticals. In those cases, rats aren’t just a nuisance — they’re a threat to health and safety, and to your business.

You might need:

- Regular pest control inspections

- Signed reports for audits

- Specific control plans for different zones

- Separate storage for cleaning products and baits

If you’re working under strict guidelines or certifications (like BRCGS or HACCP), pest control will already be part of your plan. Make sure your actions are documented and up to date.

Final Thought

Getting rid of rats in a factory takes more than one quick fix. You need to inspect the space properly, clean it up, find where the rats are getting in, and block those routes. Then you choose the right removal method and follow up with checks and prevention.

When you do all that — and keep it going — you’ll have a cleaner, safer factory. You’ll protect your stock, your equipment, your staff, and your reputation.

Even if the signs are small now, it’s worth dealing with it early. That way, the rats don’t get a chance to settle in. And you don’t end up facing a bigger, more expensive problem later.

Looking for pest control Tyne and Wear?